Tighter Control of Pipeline Safety – A Priority for Everyone

A REAL WORLD-WIDE WEB

There is an actual, physical world-wide web encircling our planet. A massive network of pipelines transporting oil, gas and various other fuels and chemicals across and between countries. For the sake of this article we will focus upon the United States but the same message goes for much of the rest of the world. The UK is a large island but even it is connected to the European mainland and across to Ireland by a number of large interconnector pipelines.

There is an actual, physical world-wide web encircling our planet. A massive network of pipelines transporting oil, gas and various other fuels and chemicals across and between countries. For the sake of this article we will focus upon the United States but the same message goes for much of the rest of the world. The UK is a large island but even it is connected to the European mainland and across to Ireland by a number of large interconnector pipelines.

In the United States the PHMSA (Pipeline & Hazardous Materials Safety Administration) are responsible for the safety of the transportation of hazardous materials, including through the countries pipeline network. Their own mission statement states: “PHMSA’s mission is to protect people and the environment by advancing the safe transportation of energy and other hazardous materials that are essential to our daily lives. To do this, the agency establishes national policy, sets and enforces standards, educates, and conducts research to prevent incidents.”

A LARGE HAZARDOUS NETWORK

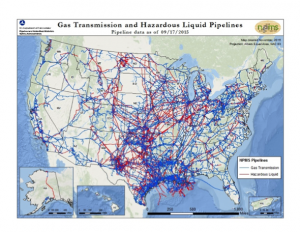

In  the wake of a number of high profile leaks and explosions the PHMSA recently announced new proposals to upgrade and update safety requirements for the country’s 3.2 million km natural gas pipeline network. This image clearly illustrates just how large and complex a network there is in the USA, much of it in densely populated areas. According to the PHMSA, the proposed rules will provide pipeline operators with regulatory clarity and certainty and recommendations for them to proactively manage pipeline integrity matters.

the wake of a number of high profile leaks and explosions the PHMSA recently announced new proposals to upgrade and update safety requirements for the country’s 3.2 million km natural gas pipeline network. This image clearly illustrates just how large and complex a network there is in the USA, much of it in densely populated areas. According to the PHMSA, the proposed rules will provide pipeline operators with regulatory clarity and certainty and recommendations for them to proactively manage pipeline integrity matters.

ENSURING JOINT INTEGRITY

Unless the anti-corrosions systems are compromised or the integrity of the system is damaged by outside influences (excavations), it is very rare for line pipe to fail. The weakest link in all pipeline systems is the bolted connections. The key to avoiding failures at these points is ensuring the joint integrity by way of correct tightening procedures. These procedures should ensure that:

- The technicians are provided with complete and accurate bolting procedures

- The technicians are trained and certified

- The equipment being used is fit for purpose, correctly maintained and calibrated

- Accurate data is gathered on the entire process, technician and equipment and safely stored for future reference

Item 4. Is the part of the process  that hasn’t necessarily been completed comprehensively or accurately in the past, but as the PHMSA are planning to expand mandatory data collection and validation requirements for system integrity management it will be a must for the future. As an example from another industry, way back in the early 1990’s the big three US automotive manufacturers (General Motors, Ford and Chrysler) demanded that all suppliers must carry out SPC (statistical process control) data collection. The cost of non-compliance – removal from the approved supplier register, they were that serious about how critical data collection was, even then. Now the pipeline industry is catching up.

that hasn’t necessarily been completed comprehensively or accurately in the past, but as the PHMSA are planning to expand mandatory data collection and validation requirements for system integrity management it will be a must for the future. As an example from another industry, way back in the early 1990’s the big three US automotive manufacturers (General Motors, Ford and Chrysler) demanded that all suppliers must carry out SPC (statistical process control) data collection. The cost of non-compliance – removal from the approved supplier register, they were that serious about how critical data collection was, even then. Now the pipeline industry is catching up.

SOON WE’LL HAVE NO CHOICE

Organizations like the PHMSA, health and safety considerations and good old common sense are driving pipeline operators across the world to take steps to ensure the integrity of their systems and they in turn are specifying these more stringent procedures to their installation and maintenance contractors. Torq-Comm offers a suite of data collection and storage hardware, software and associated accessories that surpass these requirements. Before long, we will have no choice, so it pays to upgrade your joint integrity systems and procedures now, in preparation. We can’t afford not to.