CUSTOMER TESTIMONIALS

Revolutionary Industrial Bolting Data Collection Technology

FEATURED PRODUCTS

A rugged, handheld production control system designed as an assembly aide while collecting critical hydraulic bolting data.

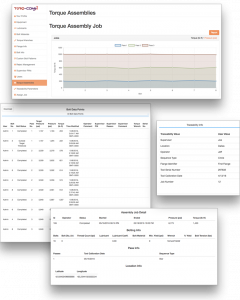

The administration center for the creation of assembly jobs, maintaining libraries of pertinent information, and the storage and reporting of all collected data.

All the capabilities of the XT1000 in addition to wirelessly adjusting pump pressures quickly and accurately from 60-80 feet away in as little as 5 seconds.

Recent News

Torq-Comm Named a Top 30 Most Innovative Tennessee Based Oil and Gas Company

April 11, 2022

Torq-Comm's innovative solutions providing data collection, safety management, software and hardware solution. recognized as Futurology names Torq-Comm in…

Torq-Comm’s Commander XT2000 Closed-Loop Wireless Hydraulic Pump Control Makes for Better Bolting

October 12, 2021

How do you drastically reduce the risks in a critical, yet often overlooked, area of construction and assembly…

IEA Shares the Nuts & Bolts About Torq-Comm

September 20, 2021

We recently had an opportunity to discuss the Torq-Comm Commander XT bolting process control, data collection, and…